Management

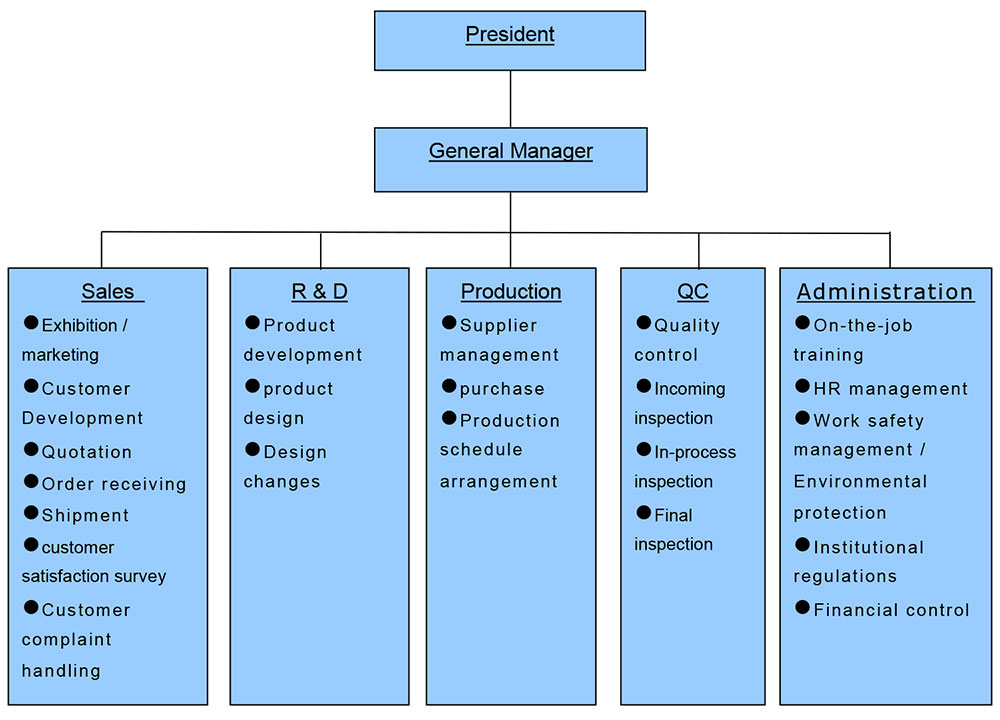

Soteck's organization has Administration, R&D, Sales, Production management and QC departments. Since product development, marketing, customer order, till production, ship to customers, we all have standard operation procedure documentation and strictly asked all of our staffs to comply with our operation procedure.

Soteck holds various professional pre-job and on-the-job trainings for all staffs; therefore each product has been supervised, controlled and detailed checked, tested by precise computers and machines. With the inspection and testing by precise digital devices, the Total Quality Management can be enforced from assembly to shipping of the production to ensure the excellence and stability of quality.